Method for testing brittleness of coatings

Brittleness of coating is a character that the metal coating changed then make the coating becomes brittle. Brittleness of coating is an important indicator of the coating quality. Brittleness of coating is more prominent especially when various electroplating additives used in more and more cases.

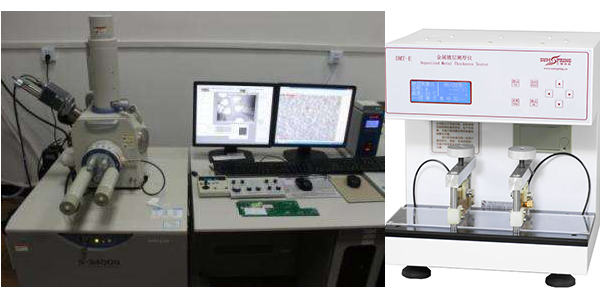

The principle of detection of brittleness is to test a test piece with coating or round wire, deformation occurs after the crack, observe the state of the coating. Commonly used methods are cup method, bending method, winding method and so on.Cup method requires professional equipment and standard tablets, etc., rarely used in the work site, commonly used method is bending method, winding method.

The bending method is to sandwich the coating test piece on the vise, In order to prevent the jaws from touching the test piece, could make a film (or other soft close) on the jaw pad and make a 90 ° bend on the test piece until the test piece is cracked. Note that the crack will appear even if not reach 90 °when brittleness of the coating reaches its high point, write down the bending angle. If there is no crack at 90 °, increase the the bending times, write down the numbers of the crack, which can be used as the relative comparison parameters of the degree of coating brittleness. Sometimes it is necessary to observe the crack state with a magnifying glass. Note that not mixed the coating brittleness with the coating binding force. If binding force is poor, when doing the bending test, coating off may not be caused by the brittleness. Therefore, when making the test piece for the test, make sure there is a good binding force for the coating and the substrate. It is recommended that the test piece be chemically degassed and then subjected to ultrasonic degreasing and electrolytic degreasing, and also a strong surface corrosion and activation, and then plating.

There is also a simple way that is to take round bars of different diameters, coated with a wire or copper wire wrapped, usually wrapped around ten or more, with a magnifying glass to observe the surface of the cracking of the case, if a diameter does not appear cracking, to use a smaller diameter rod to do, through the smaller diameter, the smaller the brittleness of the coating.

The easiest way is to bend the coating test piece on the ear side, listen to the deformation of the sound when issued, the greater the brittle, the greater the brittle sound deformation. This method is very rough, and the test piece need to be thin and have a certain degree of steel.

- PageUp:Zinc alloy

- PageDown:About Rohs